Jan 19, 2022

Flooring Inspection rethought - using innovative camera and illumination technology

Translation of the German article at "LAMINAT Magazin 2022":

The inspection of laminate floorboards has been part of Baumer Inspection's proven portfolio since 2003. In several hundred lines worldwide, flooring manufacturers rely on the quality assurance of their planks by Baumer systems. With the consistent further development of the ColourBrain® Flooring system, which has been extremely successful for 20 years, the change and trend in laminate flooring production towards deeply structured surfaces with the natural appearance of a wood structure was taken into account.

Therefore, in the further product development of the ColourBrain® Flooring 4.0 system, Baumer Inspection has focused on the following development goals, which have been implemented very successfully:

Reliable defect detection even on highly structured surfaces

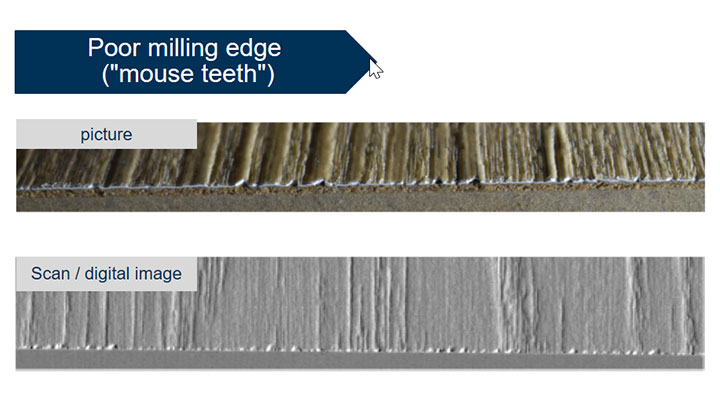

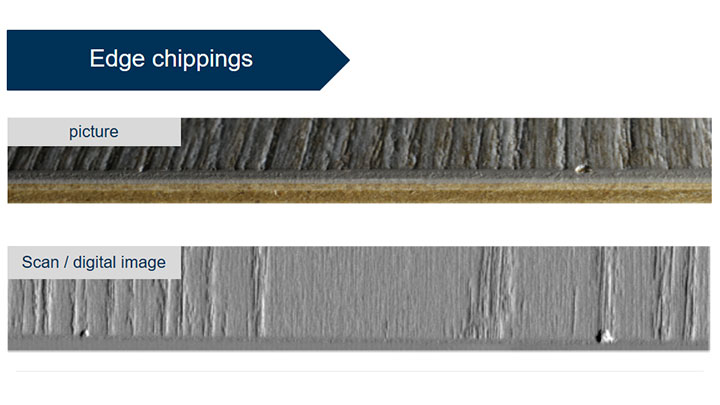

The focus of the system revision is on reliable defect detection even on highly structured surfaces. Milling defects, such as "mousing teeth" or edge chipping, are a significant defect category in the profiling area. Both lead to a downgrading of the planks and is additionally alarmed so that the machine operator can eliminate the cause of the defective milling.

In addition, the use of UV LED lights noticeably enhances the contrast between transparent and milky, as well as missing overlay layers, so that even weaker and smaller defects in the overlay can be detected.

Assignment of defects to processes

A new and helpful meaningful feature is the assignment of defects to processes in which they primarily arise. Among others, a distinction is made between:

- Profiling defects such as defects on the edges and profiles.

- Coating defects such as pressed decor particles or contamination as well as overlay defects and paper misalignment and

- Handling defects such as damage or scratches.

While the cause of profiling defects can be at least partially eliminated, thus reducing costs, the flooring manufacturer usually has no influence on the development of coating defects. However, all detected defective planks are rejected regardless of their cause. The various defects are automatically assigned to defect groups by the inspection system. Quality matrices are used to set the tolerances for each defect group.

Intuitive user interface

The Flooring 4.0 system features a new, intuitive graphical touch user interface. The Baumer "Cockpit" provides an overview of the current production. The inspection results with the plank qualities, defect logs as well as the production statistics are displayed scalable over different time periods - from the single view of a plank up to a period of several minutes or hours.

Simplification of product data management through templates

By using templates, Baumer Inspection brings order and clarity to product data management. Similar structured planks are grouped together so that there is no need to find suitable inspection settings for hundreds or thousands of different flooring items, but only for a handful of templates.

Smart Grading - Tolerating Harmless Events

Smart grading with tolerating harmless events such as loose particles and loose milling residues leads to an increase in the 1st choice rate. Harmless incidents such as loose or fluttering particles are detected by the inspection system independently, classified and tolerated, so that the plates are not degraded in these cases.

Systematic comparison of systems - across plants and groups

Consistent data management enables systematic comparison of several Flooring 4.0 systems in a plant or group, thus ensuring that the same article is assessed with the same criteria in different lines or locations.

Reduction of commissioning and maintenance times

The Flooring 4.0 are calibrated and preset in a standardized manner at Baumer so that commissioning can be carried out quickly and with the shortest possible line downtime.

Increased operational safety through self-monitoring

Due to the self-monitoring functions and the reporting of changes such as temperature rise, lighting drop, failure of computers, cameras, lights or deposits on lights or mirrors, a high level of operational reliability is achieved.

It is optimally complemented with the systems ColourBrain® V-Shape 4.0 for checking the bevel coating directly after coating application in the profiling line and ColourBrain® Clip for checking the correct clip insertion directly after clip assembly.

The graphic shows a poorly milled edge with "mouse teeth" on the left

Press download

-

Article "Laminat Magazin 2022"