Germany

de

English

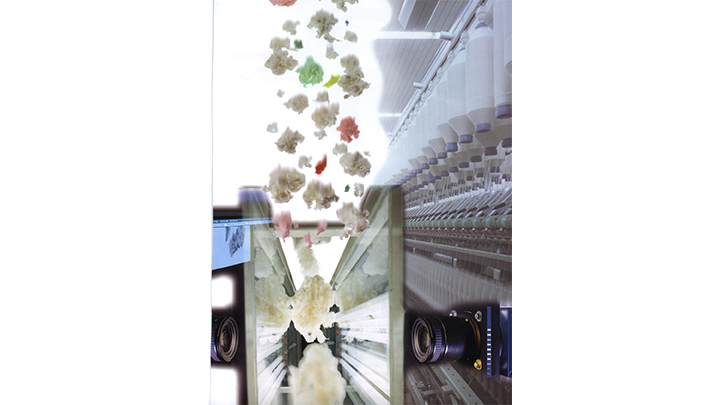

Sorting of raw cotton - OEM product VisionShield

The VisionShield system monitors the cotton flow in a wind tunnel of a spinning machine with a conveying speed of up to 20m/sec. Contaminations are detected between the cotton flocks, which are blown out by means of pneumatic nozzles.

Complex evaluation algorithms ensure that the percentage of cotton flocks in the reject is extremely low.

In more than 2000 installations worldwide, the Vision Shield OEM system has proven its worth and leads to an increase in the quality of woven textile fibers.

- About 2000 installations

- OEM partner is world market leader

- Now standard for spinning mills