Jan 12, 2023

Endless inspection for digital and gravure decorated CPL

Translation of the German article at "LAMINAT Magazin 2023":

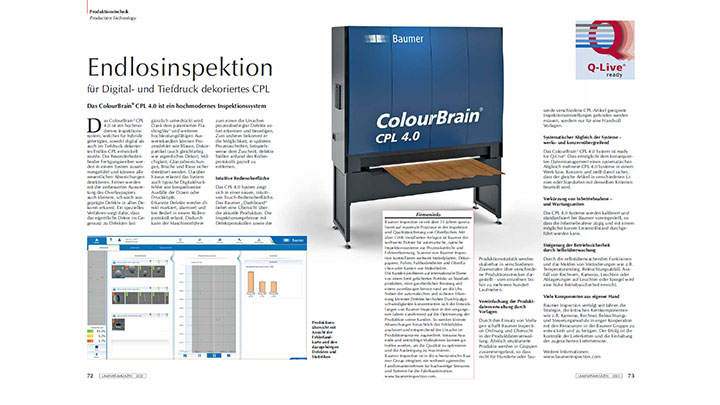

The ColourBrain® CPL 4.0 is a state-of-the-art inspection system developed for hybrid manufactured continuous CPL decorated both digitally and in gravure. The special features of both manufacturing worlds are combined in one system and can detect all significant deviations. Furthermore, with the improved evaluation of the overlay paper, even minor, weakly visible defects are detected in all decorations. A special process ensures that the actual decor, as opposed to defects, is almost completely suppressed.

Thanks to the patented FlashingSky® and other high-performance evaluation channels, process defects such as bubbles, decor particles (also of the same color as the actual decor), milkiness, gloss deviations, breaks and cracks can be reliably detected. The system also detects typical digital printing defects such as nozzle or printhead failures.

Detected defects are directly marked, alarmed and, if required, recorded in a roll log. This enables the press operator to immediately identify and eliminate the causes of process-related defects. On the other hand, the roll log enables him to remove defective areas in a targeted manner in later process steps, e.g. cutting.

Intuitive user interface

The CPL 4.0 system features a new, intuitive touch user interface. The Baumer "Dashboard" provides an overview of the current production. The inspection results with defect logs as well as the production statistics are displayed scalable in different zoom levels over different production sections - from a single to several hundred running meters.

Simplification of product data management through templates

By using templates, Baumer Inspection creates order and clarity in product data management. Similarly structured products are grouped together so that suitable inspection settings do not have to be found for hundreds or thousands of different CPL items, but only for a handful of templates.

Systematic comparison of systems - across plants and groups

The ColourBrain® CPL 4.0 system is ready for Q-Live®. This enables consistent data management to systematically compare several CPL 4.0 systems in a plant or group, thus ensuring that the same article is assessed with the same criteria in different lines or locations.

Shortening commissioning and maintenance times

The CPL 4.0 systems are calibrated and preset in a standardized manner at Baumer so that commissioning can be carried out quickly and with the shortest possible line downtime.

Increased operational reliability through self-monitoring

A high level of operational reliability is achieved through the self-monitoring functions and the reporting of changes such as temperature increases, illumination losses, failure of computers, cameras, luminaires or deposits on luminaires or mirrors.

Many components from our own production

For years, Baumer Inspection has followed the strategy of developing and manufacturing the critical core components such as cameras, computers, illumination and control modules in close cooperation with the resources in the Baumer Group. This pays off several times over, especially in the current turbulent times. The success is the control of the supply chains and the adherence to the promised delivery dates.