USA

us

English

NEW: Complete solution for the furniture industry

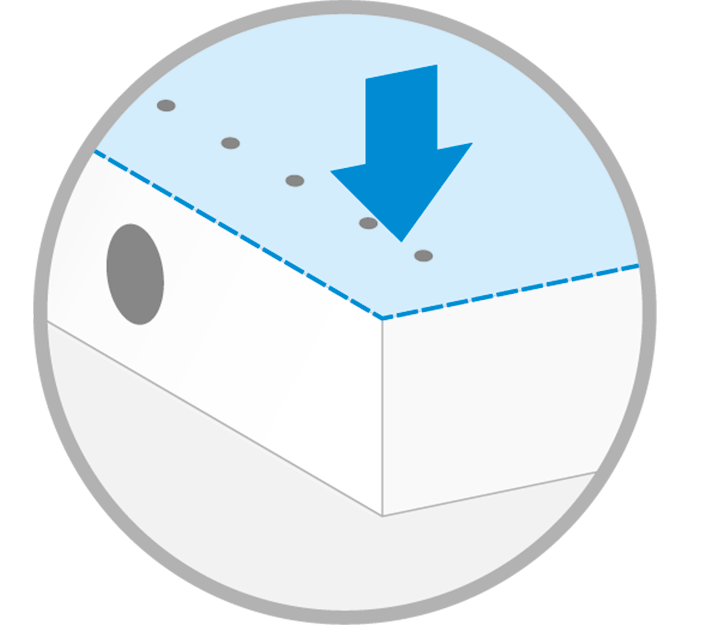

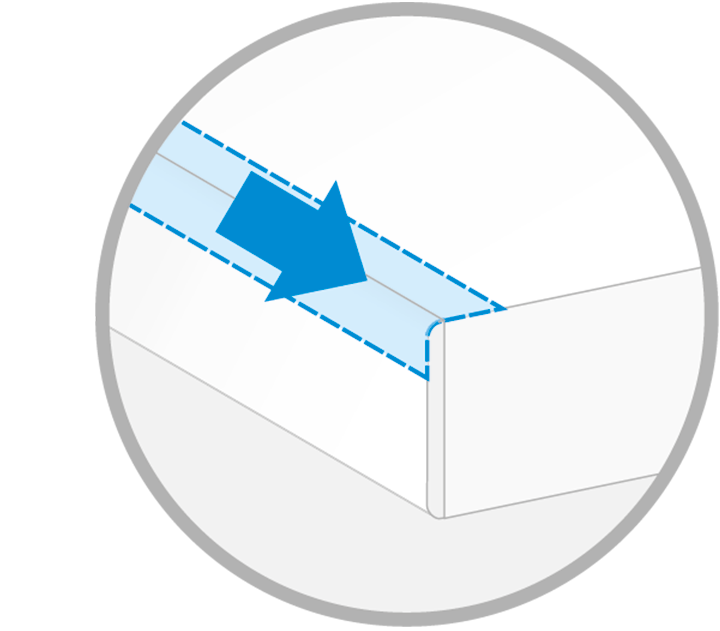

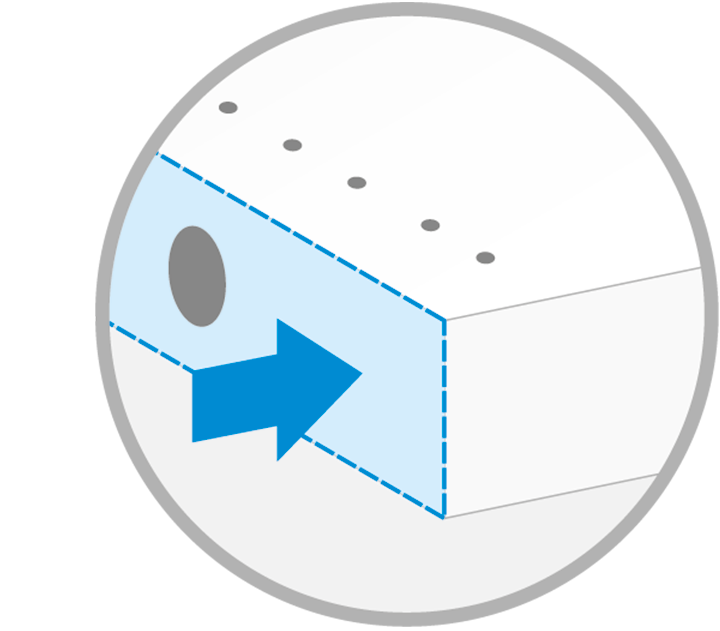

Our customized complete solution, consisting of a ColourBrain Furniture 4.0 surface inspection system and a transport system adapted to the needs of furniture production, which can be seamlessly integrated into your existing production line. This enables precise inspection from top and bottom, while very small components such as cabinet fronts are conveyed smoothly across the conveyor belt gap.

Office furniture parts in Batch size 1 production at HALI

The surface inspection system in Hali's batch size 1 production monitors around 1,200 parts per shift for all defects created in the process. The system is equipped with automatic height adjustment and inspects office parts of different heights. More information about this project, can be found here in an article of the "Möbelfertigung".

Kitchen furniture parts at VERISET

The ColourBrain® Edge inspection system inspects kitchen parts in edge processing in a batch size 1 production and thus supporting the output of 80 high-quality kitchens per hour.

Foil-coated furniture parts at BÜRSTADT Furniture

This surface inspection system, together with the ColourBrain® Edge inspection system, monitors the quality of foil-coated furniture parts in the wrapping line. Both large surfaces - top & bottom, and both narrow sides - left & right are inspected for coating defects. In addition, this system is equipped with a live display of the foil joint. Defective component segments are marked for later reject after board cutting.

Office furniture parts at ASSMANN Büromöbel

This system is integrated into a batch-size-1 production, after the cut-to-size saw. Both large surfaces are inspected and defective parts are rejected. The remaining good parts are then inspected in the edge processing machine on all four edges in a throughfeed for milling defects and incorrect application of the edge band. If the set quality criteria are not met, the part is discharged and conveyed to a so-called rework station. The operator can then decide whether this part must be reworked or remanufactured.

High-gloss furniture parts at TPS/ILCAM

In this painting line with curtain process, high-gloss furniture fronts are inspected for typical painting defects, such as inclusions. The part quality is divided into 3 defect groups - tolerable, repairable and irreparable.

High-gloss furniture parts at STILCURVI

In this production, the components are painted in curtain process in the component carpet. The ColourBrain® Paint inspection system checks the underside of the parts for spots, scratches and dots before painting. If defects are detected, the panel is turned over and the defective side is painted over. This enables a high level of material savings and optimum machine utilization.