May 12, 2023

Baumer presents the latest technology for modern flooring production at LIGNA

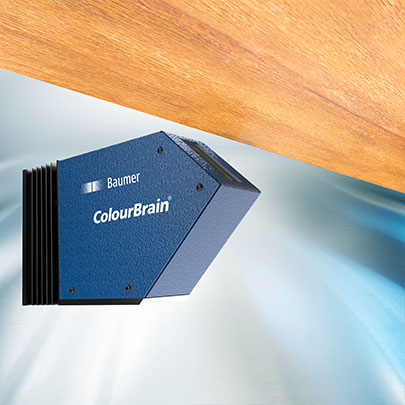

The ColourBrain® Flooring 4.0 system is the new generation of our proven system - equipped with the latest patented technology, enhanced defect detection and with a new, intuitive user interface. The result is impressive inspection results for deep structures, small edge chipping and critical color and overlay defects. The innovative system is designed for optical inspection of profiled melamine paper-coated floorboards immediately prior packaging. On request, the system design is also possible for other flooring productions, such as LVT, SPC & WPC.

It is ideally complemented by the ColourBrain® V-Shape 5.0 systems for checking the bevel coating of the V‑joint directly after coating application in the profiling line and ColourBrain® Clip for checking correct clip insertion directly after clip assembly. Defective planks are automatically rejected before packaging.

Advantages at a glance:

- Objective detection of the smallest defects, independent of decor and structure.

- Checking the profiles for presence and completeness.

- Improve your product quality through immediate process optimization.

- Q-Brain® Classification of defects and assignment to the production process.

ColourBrain V-Shape 5.0 - Improved detection of contrast and gloss based defects.

The ColourBrain® V-Shape 5.0 inspection system is the consequent further development of bevel coating inspection in flooring production. A new feature is the detection of the coating application based on the gloss properties of the still wet coating directly after application. This means that coatings that do not contrast with the substrate can now also be inspected. And this with almost identical design of the inspection heads.

The system is designed for integration in flooring lines and suitable for the high production speeds prevailing there in a very harsh environment. Due to the possible connection to the Q‑Live® management system, analyses for process optimization are possible in just a few steps.

Advantages at a glance:

- Objective detection of paint defects, now also independent of the paint colour.

- Applicable at highest production speeds and harshest environmental conditions

- Improve your product quality through immediate process optimization.

ColourBrain Furniture 4.0 - Technological leader in furniture inspection

The ColourBrain® Furniture 4.0 inspection system is a technological leader in the double-sided inspection of foil‑coated, melamine paper-coated and lacquered furniture panels. The results are impressive inspection results: The smallest surface defects such as bubbles, dents, fine cracks, scratches or shiny spots are precisely detected in their smallest size - whether in, diagonally or transversely to the feed direction. An optional drill hole inspection also checks the completeness and position of drill holes as well as the profile deviations of grooves.

The system can be used both in batch production and in batch 1 production for defect detection and process optimization. In its most powerful configuration, Baumer's newly designed illumination module is combined

with the first-class multiReflex® inspection module to detect additional gloss defects. Together with the edge extension, a 360° of furniture parts is possible.

Advantages at a glance:

- Objective detection of the smallest defects, independent of decor and structure.

- Q-Brain® Classification of defects and allocation in the production process.

- Improve your product quality through immediate process optimization.

- Drill pattern and profile deviations are checked.

ColourBrain Edge 4.0 - Unrivaled in Edge Inspection

The ColourBrain® Edge 4.0 inspection system is the next step in the improvement of defect detection and the consistent revision of all user interfaces towards a system-wide and uniform look & feel in user interface.

The system is used to inspect furniture parts in edge banding machines from various manufacturers. The detection of edge chipping, open glue joints, partially or completely missing edges and protruding edge bands are just as much part of the functional scope as the detection of geometric features such as grooves and drill holes and their differentiation from defects. The system can be used either in series production or in batch 1 production for defect detection and process optimization and ideally complements the ColourBrain® Furniture 4.0 system.

Standardized interfaces reduce the effort for integration into the processing machines to a minimum. The outstanding strength of the inspection system lies in the detection of topographical defects both on artificial edges and on veneered or wood edges. For this purpose, directional line lasers are used in addition to a proven incident light method.

Advantages at a glance:

- Reliable detection of topographical defects, such as edge bands that are too high or breakouts

- Defect detection on plastic, veneer and wood edges

- Folds, grooves and drill holes are detected and distinguished from defects

- Q-Brain® Classification of defects and allocation in the production process

- Intended for series and batch-1 production.

ColourBrain Panel 4.0 - Compact, simple & intuitive for your coating line.

The ColourBrain® Panel 4.0 system is the small and smart version for the optical inspection of melamine paper-coated fiberboards after pressing and edge trimming in the longitudinal run. Thanks to the FlashingSky® technology, precise evaluation is possible - regardless of which conveyor belt is used. Due to the reduced size to the minimum, the system can be easily integrated into your existing transport. The components are inspected on both sides for decor defects and damage with a reliable and stable detection performance. A distinction can be made between process-related defects, such as heat streaks or paper misalignment, and sporadic individual defects, such as contamination.

Checking of the synchronous pores is already integrated in the system. Here, the offset between the decor and the embossing structure is determined and non-tolerable offsets are alarmed.

Advantages at a glance:

- Small installation length, low working height - only a small gap is needed in the transport.

- Standard belt or roller transport sufficient - no vacuum transport necessary.

- Blowing off and exhausting as cleaning is sufficient.

- Q-Brain® Classification of defects and allocation in the production process.

Further Information

-

Press Release