Great Britain

gb

English

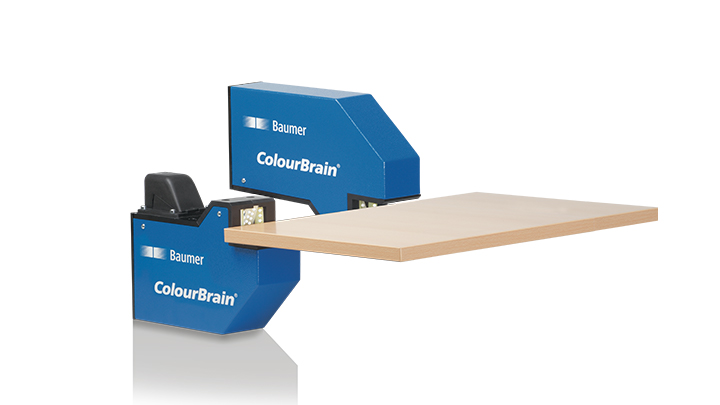

ColourBrain Furniture 4.0

- Objective detection of smallest defects, independent of decor and structure.

- Q-Brain® defect classification and assignment in the production process.

- Improve your product quality through immediate process optimization.

- Optional inspection of drill hole patterns and narrow surfaces.

- The system is suitable for both, series and batch-1 operation.

ColourBrain Edge 4.0

- Reliable detection of milling defects (edge chipping), as well as too short or too long edge bands

- Q-Brain® classification of defects and allocation in the production process

- The system is suitable for both series and batch 1 operation

ColourBrain DrillCheck 4.0

- With the smart 3D technology, drill hole patterns and grooves are reliably checked. Deviations are detected, analyzed and reported.

- The inspection is independent of the decor, structure and thickness of the components.

- Fast integration and commissioning according to the plug-and-work“ principle.

- Product change through simple Teach-In or the transfer of existing patterns.

- Improvement of the quality standard through immediate inspection after drilling.

- The system is used for process monitoring, both in series and batch 1 production.

ColourBrain X-Side 4.0

- Versatile application for the inspection of narrow surfaces on furniture parts

- Detects typical production defects and verifies the presence of drill holes.

- Objective detection of small defects, independent of decor and structure.

- Same user interface and data interfaces for combined Baumer systems.

- Classification of defects and allocation in the production process.

- Improve your product quality through immediate process optimization.

- The system is suitable for both series and batch-1 operation.